Add to Cart

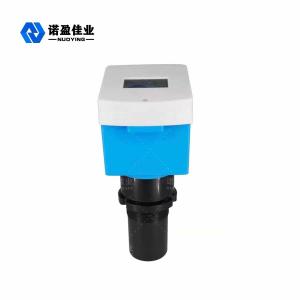

High Sensitivity NYCSUL Ultrasonic Level Gauge Alarm Setting At Any Point

The working Principle of High Sensitivity NYCSUL Ultrasonic Level Gauge Alarm Setting At Any Ponit

The working principle of the ultrasonic level gauge is that the ultrasonic transducer (probe) sends out a high-frequency pulsed sound wave when it encounters the surface of the measured material (material) and is reflected and folded back. The reflected echo is received by the transducer and converted into an electrical signal. The propagation time of the sound wave It is proportional to the distance from the sound wave to the surface of the object. The relationship between the sound wave transmission distance S, the sound speed C and the sound transmission time T can be expressed by the formula: S=C×T/2.

Because the transmitted ultrasonic pulse has a certain width, the reflected wave in a small area close to the transducer overlaps the transmitted wave, which cannot be identified and its distance value cannot be measured. This area is called the measurement dead zone. The size of the blind zone is related to the model of the ultrasonic level meter.

The probe part emits ultrasonic waves, the ultrasonic waves will be reflected when encountering a medium with a large difference in density from the air, and the reflected waves will be received by the probe part. The distance from the probe to the liquid (object) surface is proportional to the time passed by the ultrasonic wave:distance [m] = time x speed of sound/2 [m]

Design feature of High Sensitivity NYCSUL Ultrasonic Level Gauge Alarm Setting At Any Ponit

◎ reasonable design, excellent performance, simple structure, convenient installation, etc

◎ small angle probe is adopted for ultrasonic wave, with large transmission power and high sensitivity

◎ upper and lower limit setting and alarm setting at any point, can be used for continuous liquid measurement and liquid level control

Technical parameters of High Sensitivity NYCSUL Ultrasonic Level Gauge Alarm Setting At Any Ponit

| Typical application | Liquid (no stirring, foam, volatilization, etc.) |

| Product models | Nycsul-501, NYCSUL-502, NYCSUL-503 |

| The probe type | Body, split body, explosion-proof, anti-corrosion, anti-corrosion and explosion-proof |

| The antenna material | PP, PVC, PTFE, 304 |

| Measuring range | 0~ 20M (integrated), 0~40m(separate), |

| Accuracy of measurement | <0.25% (range <20 m), <0.5% (range >20 m) |

| The process temperature | 3M, 20M (deep well can measure several hundred meters, which can be customized as well) |

| Accuracy of measurement | 0.05% ~ 0.1% F. S |

| The process temperature | -20~+70C |

| Process pressure | -0.1 ~=0.1 MPa, (atmospheric pressure) |

| Electrical Interface | M20×1.5,½"NPT |

| Protection class | IP65, IP67, IP68(optional) |

| Process connection | Process connection |

| Display mode | Liquid level, distance (air height) |

| Set the output | Upper limit setting, lower limit setting |

| Signal output | 4... 20mA/ HART/ RS485/Modbus. . . |

| Protection grade | IP65, IP67, IP68(Optional) |

| Explosion-proof grade | Exia II CT6 Ga, Exd II CT6 Gb(see certificate for details) |

※Note:The product can be customized according to the specific requirements of users.